Inspection Equipment

Creating a Secure Metal Processing Experience for You

Inspection Equipment:Keyence

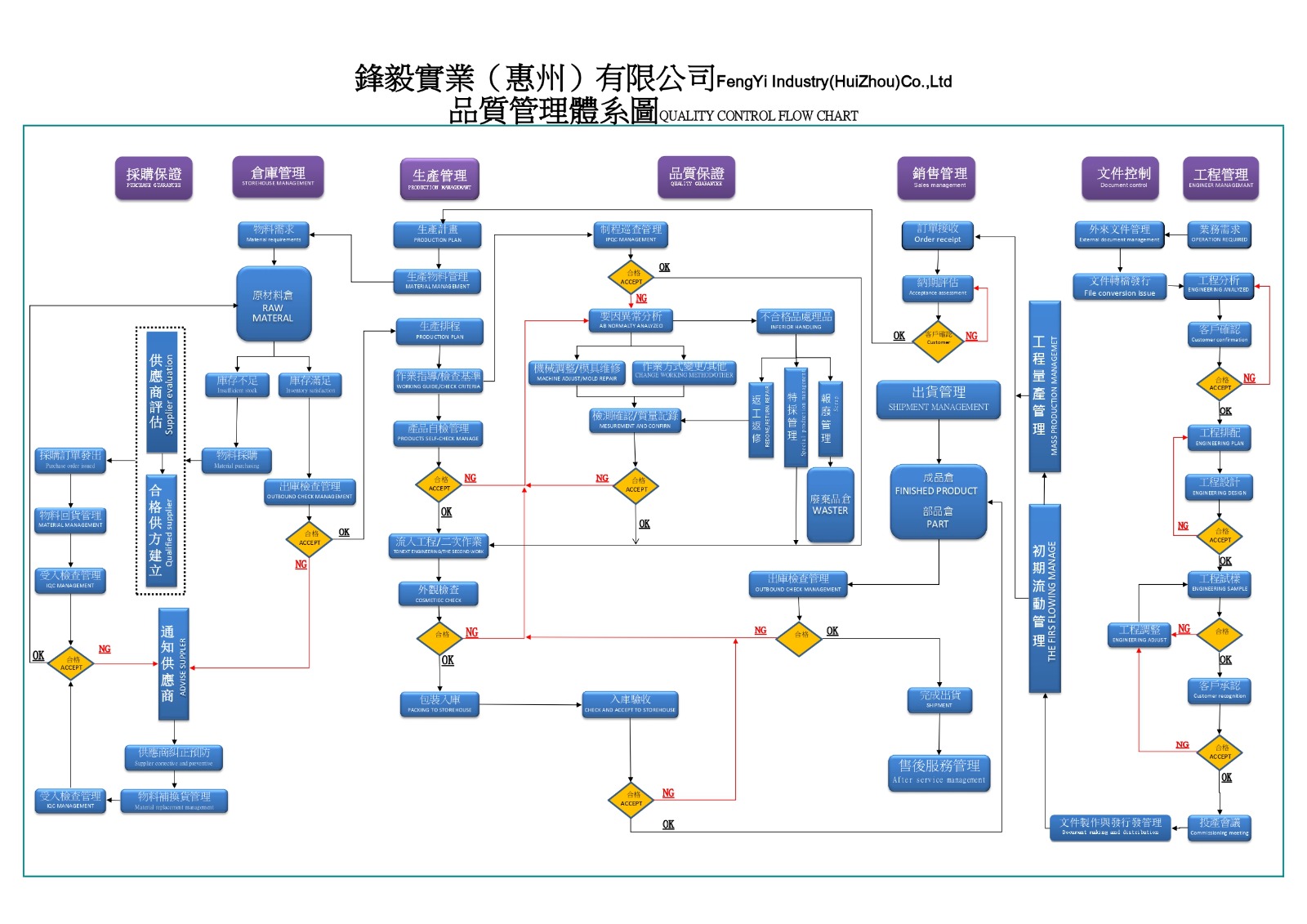

At FengYi Industrial Co., Ltd., we understand that quality is the foundation of a successful business. Therefore, we are committed to providing the most reliable metal processing services. Our inspection equipment is state-of-the-art, ensuring that every product meets strict quality standards, giving you peace of mind throughout the cooperation process.

Our inspection team uses advanced testing instruments to conduct comprehensive inspections of every detail in stamping and turning/milling processes. From raw materials to the final product, we implement multiple layers of quality control to ensure the accuracy and consistency of each item. This is not only a commitment to product quality but also a respect for the trust our customers place in us.

Throughout our service to industries such as automotive, medical, electronics, and industrial hardware, we continually refine our inspection processes to ensure customers can choose us with confidence. FengYi Industrial is founded on integrity, providing reasonably priced, high-quality products while always keeping customer needs at the center of our business.

When you work with us, you not only gain professional metal processing services but also a commitment to your peace of mind.

Processing Equipments

Experts in Precision Lathe and Milling Machine Processing

In the metal processing industry, FengYi Industrial Co., Ltd. has earned the trust of customers through professional technology and exceptional quality. We specialize in lathe, milling, and turning/milling composite machining, dedicated to providing you with high-precision, high-efficiency solutions.

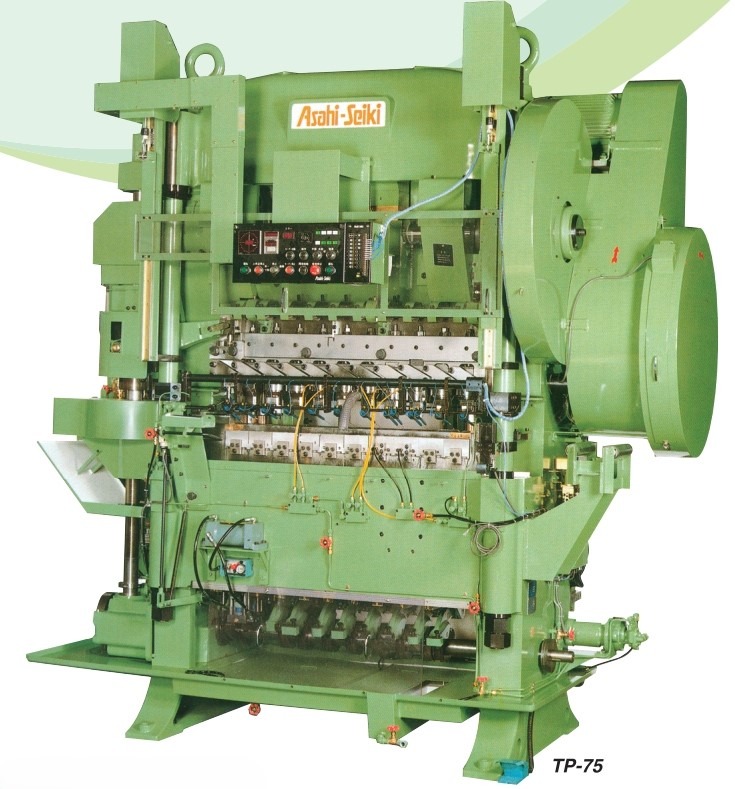

Stamping press

Press machine Asahi Seikie TP75

Professional Equipment, Precise Processing

Our lathe and milling machines are equipped with advanced technology, capable of processing a wide range of materials and sizes from 2.5mm to 200mm, all while meeting customer requirements with precision. The introduction of turning/milling composite machines enables us to complete multiple processing steps on the same machine, improving production efficiency and reducing delivery times.

Strict Inspection, Quality Assurance

Every product undergoes our rigorous inspection process before leaving the factory, ensuring that every detail is flawless. Our inspection equipment is state-of-the-art, capable of comprehensive testing for machining accuracy, surface quality, and more, giving our customers peace of mind with each collaboration.

Rich Experience, Wide Application

We have provided high-quality machining services to multiple industries, including automotive, medical, electronics, and industrial hardware, accumulating extensive experience. We understand the unique needs of different industries and can provide tailored solutions to meet those demands.

Integrity-Based, Customer First

At FengYi, we are committed to integrity and provide reasonably priced, high-quality services. We understand that customer satisfaction is our ultimate goal, and we continuously focus on technological innovation and service improvement to ensure every customer receives the best experience.

Why Choose FengYi Industrial Co., Ltd.?

In the competitive metal processing market, FengYi Industrial Co., Ltd. stands out with its outstanding technology and trustworthy service. Here are several reasons why you should choose FengYi:

Stamping press

1. Professional Technology

FengYi specializes in lathe, milling, and turning/milling composite machining, equipped with advanced machinery and technology. Whether small parts or large components, we provide high-precision processing services to meet the diverse needs of our customers.

2. Strict Quality Control

We have a comprehensive inspection process, and every product undergoes strict quality checks before leaving the factory to ensure it meets high-quality standards. This commitment ensures that you can confidently choose our products.

3. Extensive Industry Experience

FengYi has rich experience across various industries, including automotive, medical, electronics, and industrial hardware. We have a deep understanding of the needs of different industries and can provide tailored solutions to meet specific requirements.

4. Customized Services

We value our customers' needs and offer customized machining services. No matter the specifications or requirements, we adjust our processes to ensure that you receive the most suitable solution for your needs.

The press machine

5. Reasonable Pricing

FengYi always puts the customer first, offering reasonable prices. High-quality service does not necessarily mean high costs. We strive to help every customer enjoy excellent service while effectively managing their budget.

6. Integrity and Commitment

We are committed to integrity, treating every customer with consistency and respect. By choosing FengYi, you are not just selecting a supplier; you are choosing a trustworthy partner for collaboration.

7. Proactive After-Sales Service

We understand the importance of after-sales service. At every stage of the collaboration, our team provides full support to ensure your needs are addressed in a timely manner.

.jpg)

The turning/milling composite machine

Introduction to the Turning/Milling Composite Machine

The turning/milling composite machine is a high-efficiency processing equipment that combines the functions of a lathe and a milling machine, specifically designed to meet the demands of modern metal processing. Its versatility allows multiple machining operations to be completed on a single machine, significantly improving processing efficiency and flexibility.

Main Features

1. Multi-Function Processing

The turning/milling composite machine can perform both turning and milling operations simultaneously, enabling it to process complex part shapes, reduce processing steps, and improve production efficiency.

2. High Precision and Stability

The machine is equipped with a high-precision control system, ensuring stable accuracy throughout various machining processes and meeting strict industrial standards.

3. Reduced Process Conversion

Traditional machining requires multiple machines to complete different processes. The turning/milling composite machine can perform all processes on a single machine, shortening machining time and reducing the cost of process conversion.

4. Flexible Design

The turning/milling composite machine can be customized according to customer needs, adapting to different materials and part processing requirements, meeting the demands of various industries.

5. Advanced Operating Interface

Equipped with an intuitive digital control interface, the machine is easy to operate, reducing the learning curve for operators and improving work efficiency.

Application Areas

The turning/milling composite machine is widely used in industries such as automotive, aerospace, medical devices, electronics, and industrial hardware. It is especially suitable for machining high-precision parts and complex-shaped components.

Introduction to the Lathe

A lathe is a widely used machine tool in metalworking, specifically designed for cutting cylindrical or other shaped workpieces. It combines the rotational movement of the workpiece with the linear feeding motion of the tool, enabling a variety of machining processes, such as turning, milling, drilling, and threading.

Lathe

Main Features

1. High Precision Machining

Lathes offer superior machining accuracy, capable of producing high-quality workpieces in a short amount of time, meeting stringent industrial standards.

2. Versatility

In addition to basic turning functions, modern lathes can be equipped with various attachments, such as tool holders, drilling heads, and threading devices, expanding their processing capabilities to meet diverse needs.

3. Stability

The lathe is designed for sturdiness and smooth operation, effectively reducing vibrations and ensuring stability during the machining process, thereby improving product quality.

4. Ease of Operation

Modern CNC lathes are equipped with user-friendly interfaces and automation features, making it easy to operate, even for beginners.

5. Flexible Design

Lathes can be customized according to customer needs, adapting to different materials and workpiece shapes, providing solutions for a wide range of industries.

Application Areas

Lathes are widely used in industries such as automotive, aerospace, medical devices, electronics, and industrial hardware. They are especially suitable for the production of cylindrical parts, such as shafts, bushings, and gears.

Introduction to the Milling Machine

A milling machine is a specialized piece of machinery used in metalworking, primarily designed for cutting and shaping workpieces. It is especially suitable for machining flat surfaces, curved surfaces, grooves, and various other shapes. The machine achieves high-efficiency machining by combining the rotational motion of the milling cutter with the feeding motion of the workpiece, making it capable of handling complex cutting tasks.

The milling machine

The milling machine

Main Features

1. High Precision Machining

Milling machines offer exceptional machining accuracy, capable of producing parts that meet strict dimensional requirements, ensuring that the product quality adheres to high standards.

2. Versatility

Milling machines can be equipped with a variety of different tools, enabling a wide range of machining operations, including milling, drilling, threading, and more, making them highly adaptable to various machining needs.

3. Stability and Reliability

The milling machine's robust structure ensures smooth operation, effectively reducing vibrations and improving stability during the machining process, which enhances the consistency and reliability of the product.

4. Ease of Operation

Modern CNC milling machines are equipped with intuitive user interfaces and automation features, simplifying the operating process, allowing operators to easily master the machine and quickly complete machining tasks.

5. Flexible Design

Milling machines can be customized according to customer requirements, making them suitable for processing different materials and workpiece shapes, providing efficient solutions across a wide range of industries.

Application Areas

Milling machines are widely used in industries such as automotive, aerospace, medical devices, electronics, and industrial hardware. They are especially suitable for machining parts with complex shapes and fine structures, such as molds, brackets, and gears.